Blog

The Unsung Hero of Eyewear Repair: A Guide to the Eyewire Shaper Optical Plier

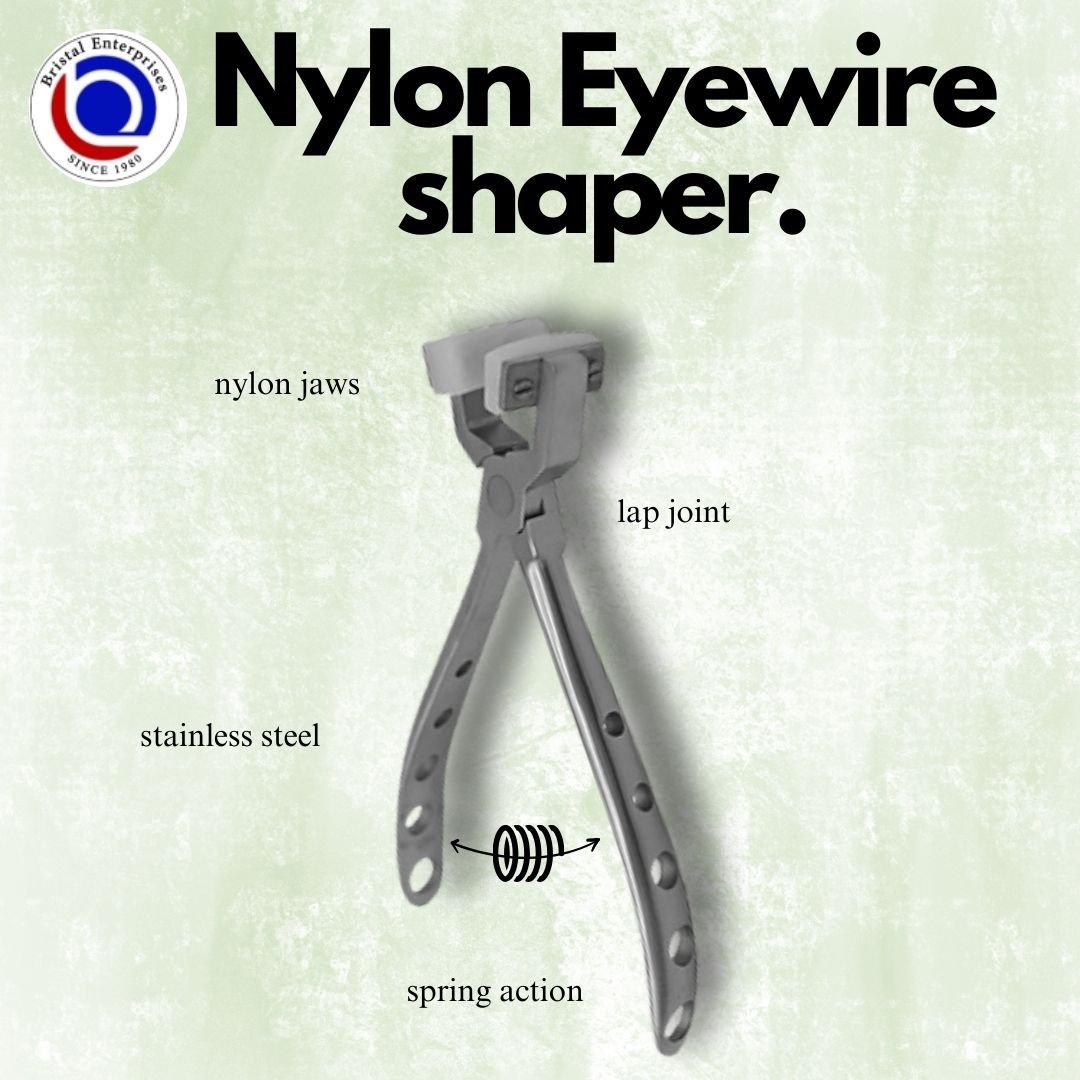

Eyewire Shaper Optical Plier

For anyone who has ever worn glasses, the frustration of a misaligned frame is all too familiar. But behind every perfect fit and seamless repair is a specialized set of tools. Among the most fundamental is the Eyewire Shaper Optical Plier, an indispensable instrument that ensures the structural integrity and aesthetic perfection of metal frames.

Often overlooked in favor of more flashy tools, the Eyewire Shaper is the workhorse responsible for maintaining the shape of the frame’s eyewire—the rim that holds the lens in place. Understanding this tool is key to professional eyewear repair and dispensing.

Key Features and Design Qualities

The Eyewire Shaper is designed with precision and durability in mind. Its unique shape is what makes it perfectly suited for the specific task of shaping the metal rims of glasses.

1. The Jaw Design (Concave and Convex)

The most defining feature of the Eyewire Shaper is its specialized jaws:

- Concave Jaw (Rounded): This curved side is designed to cradle the metal eyewire. It ensures that pressure is applied evenly, preventing kinks or flat spots from forming during the shaping process.

- Convex Jaw (Round or Half-Round): This side fits snugly into the curve of the concave jaw. It acts as the forming surface, allowing the technician to gently roll or press the eyewire back into its desired circular, oval, or rectangular shape.

2. Materials and Construction

Quality is paramount for optical tools, as they require fine motor control and consistent performance:

- Stainless Steel/High-Grade Alloy: Most professional shapers are made from durable, corrosion-resistant stainless steel. This longevity is crucial, as the tool is constantly exposed to skin oils and cleaning solutions.

- Smooth Finish: The working surfaces of the jaws are polished smooth to prevent scratching or marring the delicate metal finish of the frame.

- Box Joint: High-end models often feature a box joint, which provides superior stability, prevents wobble, and ensures the jaws meet perfectly and consistently, enhancing precision.

3. Handle and Ergonomics

While the focus is often on the jaws, the handle design is critical for the technician:

- Comfort Grips: Often coated in vinyl or a polymer, the handles provide a secure, comfortable grip for extended use.

- Spring Mechanism (Optional): Many models include a leaf spring or coil spring to keep the jaws open when not in use. This reduces hand fatigue and speeds up repetitive tasks.

Primary Uses in Optical Dispensing

The Eyewire Shaper is used extensively throughout the lifecycle of a pair of metal-rimmed glasses, from initial assembly to final repair.

1. Correcting Lens Insertion Strain

When a new lens is fitted into a frame, it must be the correct size. If the lens is slightly too large, it can strain the eyewire, pulling it out of shape. The shaper is used to gently enlarge or reform the curve of the eyewire to perfectly accommodate the lens without forcing it.

2. Repairing Twisted or Deformed Frames

Accidents happen. If a frame is bent or twisted out of shape (e.g., sat upon, dropped, or stretched), the Eyewire Shaper is the primary tool used to re-establish the original, symmetrical curve of the rim. This is essential for ensuring the lens sits flush and the overall frame symmetry is restored.

3. Closing the Frame Joint

After a lens is inserted into a full-rim metal frame, the joint (where the eyewire opens and closes) must be secured. The shaper is often used in conjunction with a snipe-nose plier to ensure a perfect, gap-free closure of the screw joint or lock block, guaranteeing the lens is held securely.

4. Adjusting Frame Shape for Aesthetics

Sometimes, a minor adjustment to the horizontal or vertical curve of the lens rim is needed to match the wearer’s facial contour or to achieve a specific aesthetic tilt. The shaper allows for these subtle, calculated adjustments to the frame’s form.

Qualities of a Professional-Grade Tool

An optician relies on their tools to provide quality service. When selecting an Eyewire Shaper, look for these professional qualities:

- Precision and Alignment: The jaws must align perfectly, with no play or unevenness, ensuring consistent shaping.

- Non-Marring Surface: The material and finish of the jaws must be completely smooth to protect the customer’s frame finish, especially high-gloss or coated metals.

- Leverage and Control: The tool must offer adequate leverage to manipulate strong frame materials (like titanium or stainless steel) while still providing the fine control needed for precise, millimeter-level adjustments.

- Durability: As a tool used daily, it must withstand constant stress without the jaws warping or the joint becoming loose.

In essence, the Eyewire Shaper Optical Plier is the specialized device that turns a damaged, misshapen frame back into a perfectly formed ocular device. Its design is a testament to the blend of engineering and artistry required in the field of opticianry.